Manufacturing and Non-manufacturing Costs: Online Accounting Tutorial & Questions

![]()

Table 2.2 provides several examples of manufacturing costs at Custom Furniture Company by category. Table 1.2 provides several examples of manufacturing costs at nonmanufacturing costs Custom Furniture Company by category. Table 2.3.1 provides several examples of manufacturing costs at Custom Furniture Company by category. Cost of goods sold is usually the largest expense on the income statement of a company selling products or goods.

- Similarly, the amount not yet allocated is not an indication of its current market value.

- Therefore, parts have a variable nature; the amount of raw materials bought and used changes in direct proportion to the amount of valves created.

- For the past 52 years, Harold Averkamp (CPA, MBA) has worked as an accounting supervisor, manager, consultant, university instructor, and innovator in teaching accounting online.

- “Business in Action 2.6” provides examples of nonmanufacturing costs at PepsiCo, Inc.

Differences between management and tax accounting

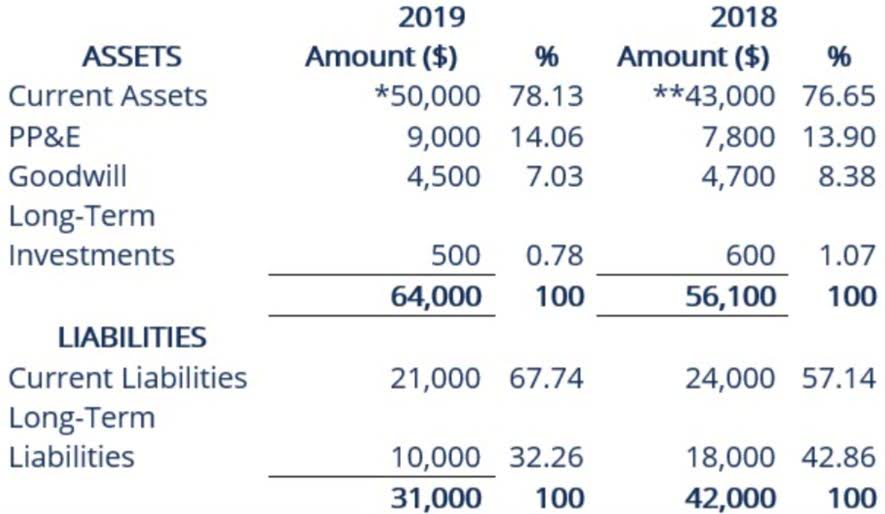

This article looks at meaning of and differences between two main cost categories for a manufacturing entity – manufacturing cost and non-manufacturing cost. The resulting unit costs are used for inventory valuation and for the calculation of the cost of goods sold. Things that are resources owned by a company and which have future economic value that can be measured and can be expressed in dollars. Examples include cash, investments, accounts receivable, inventory, supplies, land, buildings, equipment, and vehicles.

Manufacturing overhead cost:

Overhead costs refer to the expenses incurred by a service-based organization that cannot be directly attributed to a specific service or function. These costs are essential for the smooth operation of the organization and play a significant role in determining the overall profitability. Another technique is the use of time-driven activity-based costing (TDABC). This method focuses on the time required to perform various service activities. By assigning costs based on the time spent on each activity, organizations can better assess the cost-efficiency of their service processes. Overall, so far we have covered different types of product (manufacturing) and period (nonmanufacturing) costs.

Top 5 Career Options for Accounting Graduates

- In other words, the amount allocated to expense is not indicative of the economic value being consumed.

- Small, inexpensive items like glue, nails, and masking tape are typically not included in direct materials because the cost of tracing these items to the product outweighs the benefit of having accurate cost data.

- The general guidelines and principles, standards and detailed rules, plus industry practices that exist for financial reporting.

- Direct materials should be distinguished from indirect materials (part of overhead costs), about which we will talk later.

- Inventory in a manufacturing company is items purchased (or created) by a company for (a) production of other parts (raw materials or work-in-process) or (b) selling to customers (finished goods).

These costs do not specifically contribute to the actual production of goods but are essential to ensure overall functioning of the business. Manufacturing costs refer to those that are spent to transform materials into finished goods. Period costs (also called nonmanufacturing costs) are costs necessary income statement to maintain business operations but are not a necessary or integral part of the manufacturing process. They are matched with the revenues of a specific time period rather than included in the cost of the goods sold. PepsiCo, Inc., produces more than 500 products under several different brand names, including Frito-Lay, Pepsi-Cola, Gatorade, Tropicana, and Quaker.

While depreciation on manufacturing https://www.bookstime.com/ equipment is considered a manufacturing cost, depreciation on the warehouse in which products are held after they are made is considered a period cost. While carrying raw materials and partially completed products is a manufacturing cost, delivering finished products from the warehouse to clients is a period expense. In summary, the section on “Cost Measurement Techniques for Service Industries” explores approaches such as activity-based costing, time-driven activity-based costing, customer profitability analysis, and cost benchmarking. These techniques help service industries gain insights into their cost structures, optimize resource allocation, and make informed business decisions. Remember, the choice of allocation method depends on the organization’s specific needs, available data, and management’s preferences. By understanding these methods, we can better assess the true cost of providing services and make informed decisions.

This account is a non-operating or “other” expense for the cost of borrowed money or other credit. The amount of interest expense appearing on the income statement is the cost of the money that was used during the time interval shown in the heading of the income statement, not the amount of interest paid during that period of time. You should consider our materials to be an introduction to selected accounting and bookkeeping topics (with complexities likely omitted).